Precision solutions and quality grinding

Do you require µ-precision grinding of your high-grade cutting knife? So that only the material that needs to be removed is removed? Do you want your circular knife to be ground with a precision surface-grinding machine from Jung that uses a free-rotating rotary table? Then you've come to the right place!

Trauwert GmbH: Our three cutting-edge divisions

In contract manufacturing, Trauwert GmbH also µ-precision surface and profile grinding of slide and roller guides. Among other things, this includes µ-precision grinding of the clamping jaws into the chuck body (slide guide) or sharpening circular knives with diameters of up to 400 millimetres, which are required, for example, for cutting hydraulic hoses.

The manufacture of cutting punches along with the production of cutting and embossing tools for moulds and special machine assemblies are also part of the contract manufacturing sector. With a maximum of 600 x 300 millimetres, our machines offer a considerably large grinding area.

Whether it’s a Diaform head dresser, Jung-PA37K head dresser or Jung-PA130T table dresser: Trauwert GmbH restores dressers to factory-fresh condition. Overhauling the mechanical assemblies ensures sustainability and avoids expensive new acquisitions. Application areas for these assemblies are the 100 percent mechanical profiling of grinding wheels as well as the automatic profiling of grinding wheels using freely programmable CNC control technology.

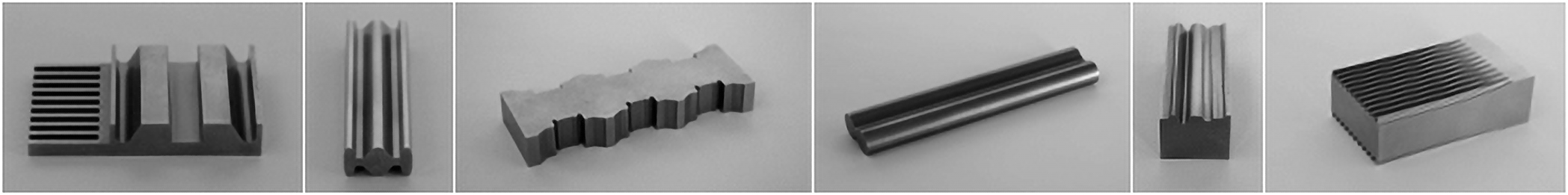

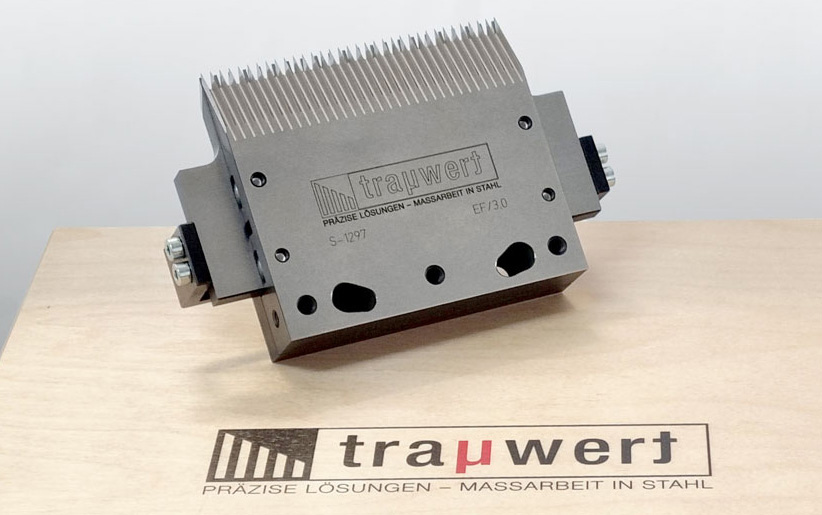

The patented roller bearing-mounted clipper trimmers are used by reputable companies mainly in the production of brushes, brooms, paintbrushes and for all types of tufting operations. Trauwert clipper trimmers can be used to cut filaments made of various materials, including plastics, natural hair and bristles, or wires. Whether you manufacture shaving brushes, cleaning brushes, brooms, household floor scrubbers, toothbrushes, paintbrushes, food brushes or heavy-duty wire brushes - there is virtually no piece of bristled equipment that cannot be processed with Trauwert clipper trimmers. On request, Trauwert clipper trimmers are also able to contour brush profiles in conjunction with freely programmable robot systems. We also produce custom toothings on request. Just ask us! We will gladly supply you with larger or longer clipper trimmers to suit your individual needs.

Clipper trimmer 100 mm

Extra-fine toothing

For example used in the production of dental brushes

Clipper trimmer 150 mm

Medium-wire toothing

For example used in the production of asphalt cleaning brushes

Clipper trimmer 200 mm

Medium toothing

For example used in the production of clean room broomsManufacture of high-speed slitting knives in conjunction with drive units for eyelet slitting machines. The latest division established by Trauwert GmbH manufactures cutting tools and drive heads for the textile industry. These can be used, for example, for high-precision cutting operations on stainless steel and plastic. The clipper trimmers used in the textile industry for precision cutting of plastic and metal eyelets are available in the basic version with a width of 80 millimetres. Custom dimensions are available on request.